More than 40 years ago, Donaldian proposed measuring the quality of healthcare by observing its structure, process and outcomes.

Measure access of delivery of healthcare services by clinicians & providers, such as using guidelines for care of diabetes patients.

Programma’s of hospital generally focus on issue’s identified by regulatory or accreditation. Reviewing the work of oversight committees and studying credentialling process.

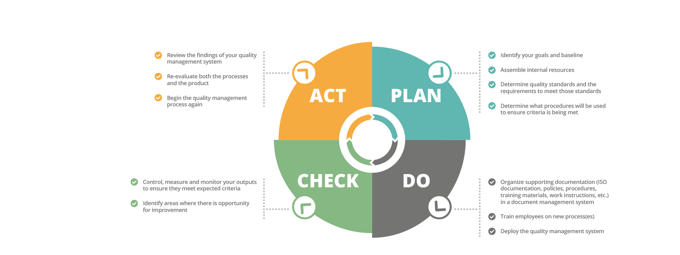

The Deming cycle is a model of a logical sequence of four representative steps continuous quality improvement and learning.

The Deming Cycle – Procedure

When to Use Plan – Do – Check act

ISO (International Organization for Standardization)

a. Champions

b. Black Belts

c. Green Belts

d. Yellow Belts

a. overproduction

b. Unnecessary stock

c. Inefficient transportation

d. waiting times

e. Rejects & defects

f. Inappropriate processing

Groups or people oriented. A quality circle is a participationary management technique that insists the help of employees in solving problems related to their own job.

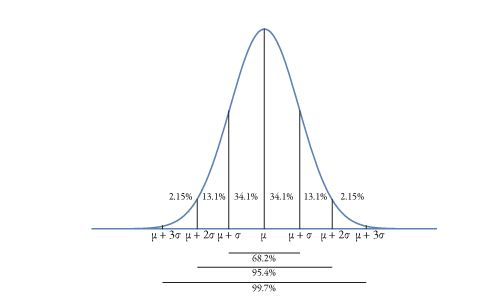

Six sigma at many organizations simply means a measure of quantity that strives for near perfection. It is a disciplined data-driven approach and methodology for eliminating defects (driving towards six standard deviations between the mean and the nearest specification limit) in any process – from manufacturing to transactional and from product to service.

The statistical representation of six sigma describes quantitatively how a process is performing. To achieve six sigma, a process defect is defined as anything outside of customer specifications. A six sigma opportunity is then the total quantity of chances for a defect. Process sigma can easily be calculated using a Six Sigma Calculator.

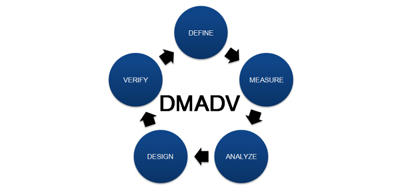

Six Sigma has 2 key methodologies. DMAIC and DMADV. DMAIC is used to improve an existing business process. DMADV is used to create new product designs or process designs in such a way that it results in a more predictable, mature & defect free performance. Sometimes, a DMAIC project may turn into a DFSS project because the process in question requires complete redesign to bring about the desired degree of improvement.

Basic methodology consists of the following steps:

Some people have used DMAICR(Realize). Others contend that focusing on the focusing on the financial gains realized through Six Sigma is counter-productive & that said financial gains are simply by products of a good process improvement. Another additional flavor of design for six sigma is the DMEDI methods.

This process is almost exactly like the DMDAV process, utilizing the same toolkit, but with a different acronym. DMEDI stand for define, measure, explore, develop & implement.

Process Capability = 6s

This represents a more pragmatic & realistic definition of process capability, since covering the population and measuring the quality characteristic to determine sigma is almost impossible, given the volumes of production and the like.

To process planners the figure of process capability is probably not as useful as the measure which indicates how well the process is doing with respect to the specifications indicated for the quality characteristic in question. Therefore, if the Upper Specification Limit (USL) & the Lower Specification Limit (LSL) are fixed for a certain important quality characteristic, then it is important to know whether the process can ‘hold tolerance’ or not. This ability determined by the Process Capability Index, Cp, defined as:

Cp= USL-LSL/6s

The important resources or inputs of the organization are the following if these are checked & controlled, there can be process control also. What will be the methods of control or how the mechanism of control can be devised has been given below:

If all these parameters in respect of the manpower deployed in the organization is taken care of the human error in process can be reduced to the significant level.

Does it meet the requirement of production?

Does it meet the requirement of process capability?

Is it appropriately laid down?

Is it easy to maintain and operate?

Is it easy to set up?

Does it exhibit any drift over time?

There is need of designing, procurement and installation of the right kinds of machines. These machines are maintained well, there is no down time. These machines are utilized adequately. The quality can be ensured.

Is the material of the right (desired) physical and chemical (or other) properties?

Is the volume, and the manner of receipt appropriate?

Is it free from impurities?

Is it stored appropriately prior to production/processing?

Is it likely to be mixed up with the ‘material-in-process’?

Is the material suitable for processing changes?

Is it liable to stock-outs/deterioration prior to processing?

The materials management and inventory control is an important aspect of the management. The materials are important resources for any process.

Is the appropriate method documented?

Does the method ensure the desired outcome?

Is the method safe?

Is it efficient?

Does it dovetail with other methods/ processes in the organization/ prior or next process?

Is there a means to improve the method?

Is the working environment appropriate?

The quality assurance depends much upon the right methods of doing things are at the right place. There are available, understood and being practiced rightly will ensure the process control.

Is there a clearly defined unit of measurement?

Is there an appropriate standard?

Are the right means of measurement available?

Is there a provision of calibrating all measurements devices? And regularly?

Are the measurement devices easy to read?

Are the measurement stimulate improvement or corrective action, where needed?

Are the measuring devices suitably stored?

There should be standard methods of measurements, not only that: the tools which are being used for the measurement of all other activities are also measured and calibrated for their accuracy. This is important aspect of the process control.

If we accept that the system is combination of these five elements, and any process exhibits a certain amount of variation on account of randomness in the elements of system itself. the variation will be acceptable as long as the system is able to deliver its output as planned and the system as a whole does not show any drift in consistency.

If the system has to be stable, exhibiting minimum of variation, the focus must be on the five elements as enumerated above. The figure above indicates the relationship between the variation of each of the five elements. If we are able to reduce the variation of each of these elements, we will bring our system into a state of control. The required output will be consistent over the time.

The housekeeping is an important component of any hospital. It is not only important from the point of view of the patients or their attendants but also from the point of view of the service providers. The work environment improves, the efficiency of the employees, is a proven fact. The “5S” technique is very useful for any health care organization, for improved housekeeping.

“5S” stands for Japanese words- all starting with ”S”, these can be translated into English words also starting with ”S”. Therefore it is not necessary to remember “5S” in Japanese, what is important is to understand what it conveys, and practice it, rather than just memorizing the words.

Japanese in their language call these steps as SEIRI (Sorting), SEITON (Segregating), SEISO (Shine/sweep), SEIKETSU (Standardize) and SHITSUKE (Sustain/ self-discipline).

SEIRI (Sorting): Sorting is about separating the things which are necessary for the job from those that are not, keeping the number of necessary ones as low as possible and at a convenient location.

SEITON (Segregating): It is a question of how quickly you can get the things you need and how quickly you can put them away. Just making an arbitrary decision on where things go is not going to make you any faster. Instead, you to analyze why getting things out and putting them away takes so long. You have to study this for both the people using the things frequently and those who seldom use them.

SEISO (Shine/Sweep): Everyone is a sweeper. Cleaning should be done by everyone in the organization, from the managing director to the sweeper. This is why in japan, they do not need street sweepers in residential areas. Every family is responsible for cleaning the pavement in from of their houses. Therefore, what they need are rubbish collectors.

SEIKETUS (Standardization): Standardization means continually and repeatedly maintaining organization through neatness and cleaning. As such, it embraces both personal cleanliness and the cleanliness of the environment. The emphasis here is on visual management and “5S” standardization.

SHITSUKE (Sustain/Self-discipline): Self-discipline means instilling the ability of doing things the way they are supposed to be done. The emphasis here is on creating a workplace with good habits. By teaching everyone what needs to be done and having everyone practicing it.

In industries the “5S” has been applied for better housekeeping and it is equally relevant for the health care organizations.